Checkerspot Brewing

We built Checkerspot’s original location in Federal Hill in south Baltimore. After 5 years, they stepped into a whole new facility. This install started with removing the 20bbl NSI brewery at Dogfish Head Miami, transporting all the equipment back and reinstalling it. This required a lot of logistics, a couple sub contractors to help with transport in Miami, layout changes to the brewhouse, as well as cellar tanks, packaging and grain handling. This project started in January and ran into September. It was a long facility build out, as well as production install, but we mostly had a lot of fun doing it.

Cushwa Brewing

We have worked with Cushwa since their expansion to keep them meeting their production demands. It started with giving them a turnkey install on a 15bbl ABE system, and has included adding much more cellar capacity as their demand has grown.

South County Brewing

Our project at South County in York Pa includes a 30bbl Kasper Schulz brew house, relocating the 15bbl SK brew house from their old facility and installing a 500gal Vendome still. We installed everything on the process end and assisted Schulz with installation of their state of the art, fully automatic brew house.

The Reckless Shepherd

When Frisco Taphouse and Reckless Aleworks decided it was time to consolidate into a single facility, we took a 7bbl pub system and combined it with their 20bbl production system. This was all shoe horned into a single room. With a high capacity club, restaurant and bar, keeping the foot print of production small was important. There were a lot of modifications required to make two systems run off of a single boiler, grain handling system and chiller. But the end result is a single brewer can do 90% of the work solo.

Bell’s MBT Brautechnik

We have worked with MBT Brautechnik since 2015. This was a project at Bell’s to create a scaled down version of their 200HL system for R&D.

Hopkins Farm Brewing

The Hopkins family decided to mix brewing into their produce, grain and malting operation. They selected an ABE 10bbl system, which is a fantastic choice, and we had the pleasure of installing their production equipment. We made sure the installation complimented the timber frame barn they built for their new facility, while operating efficiently. We also worked closely with their contractors to ensure everyone knew the needs of the end user.

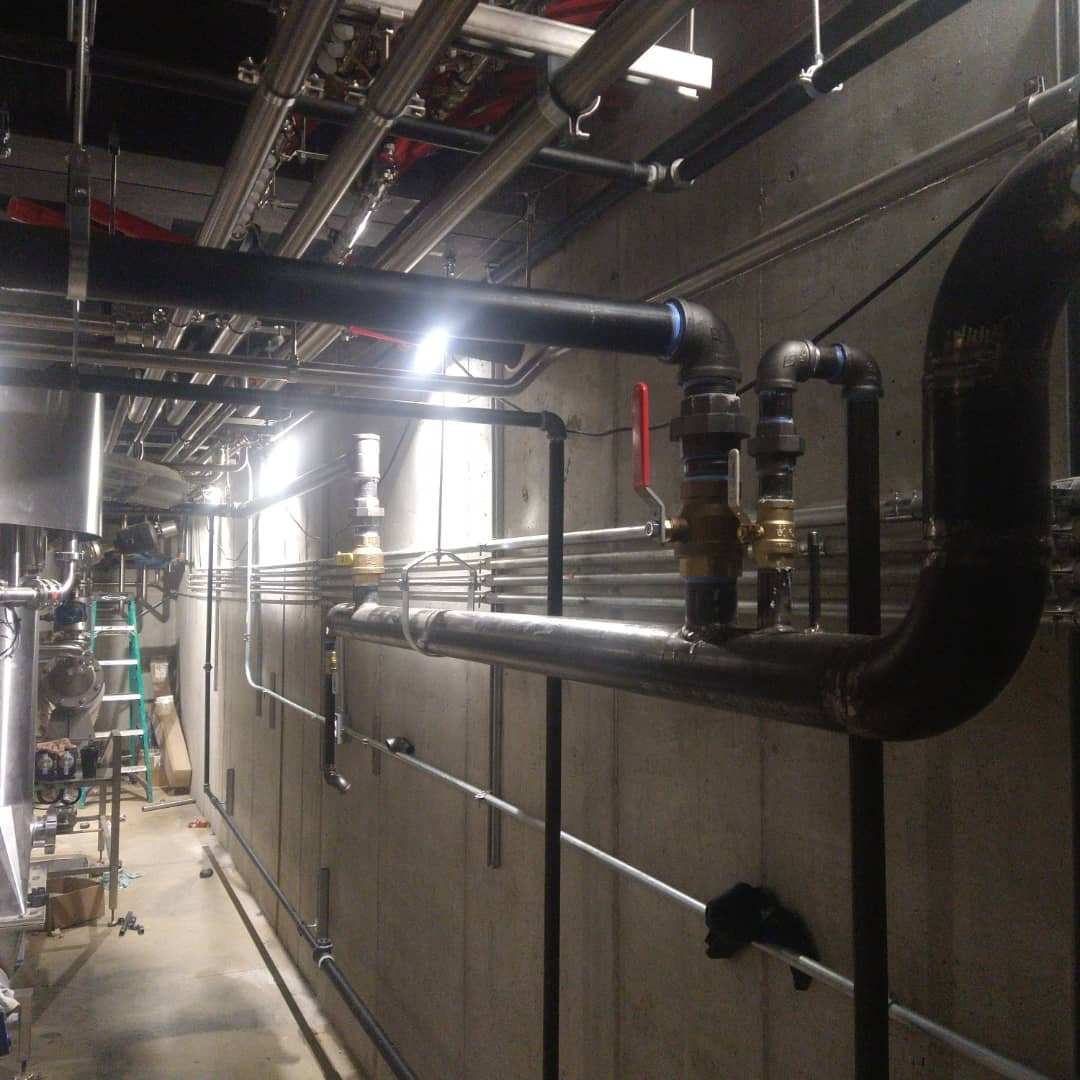

Plant Heating

Any operator knows how much they depend on their boiler. We recommend Rite Engineering for that task. Simplicity in a clean package and great support. We compliment that with a good layout that optimizes treatment, service and operation.